In 1940, Masseria Rifisa was a tobacco manufacture. Tobacco, in fact, was the main crop during the first years of twentieth century and it took a whole year of work.

Salento is a land rich in timeless culture and traditions. Tobacco and “tabacchine” history are a milestone that piece together vicissitudes of people with a strong identity.

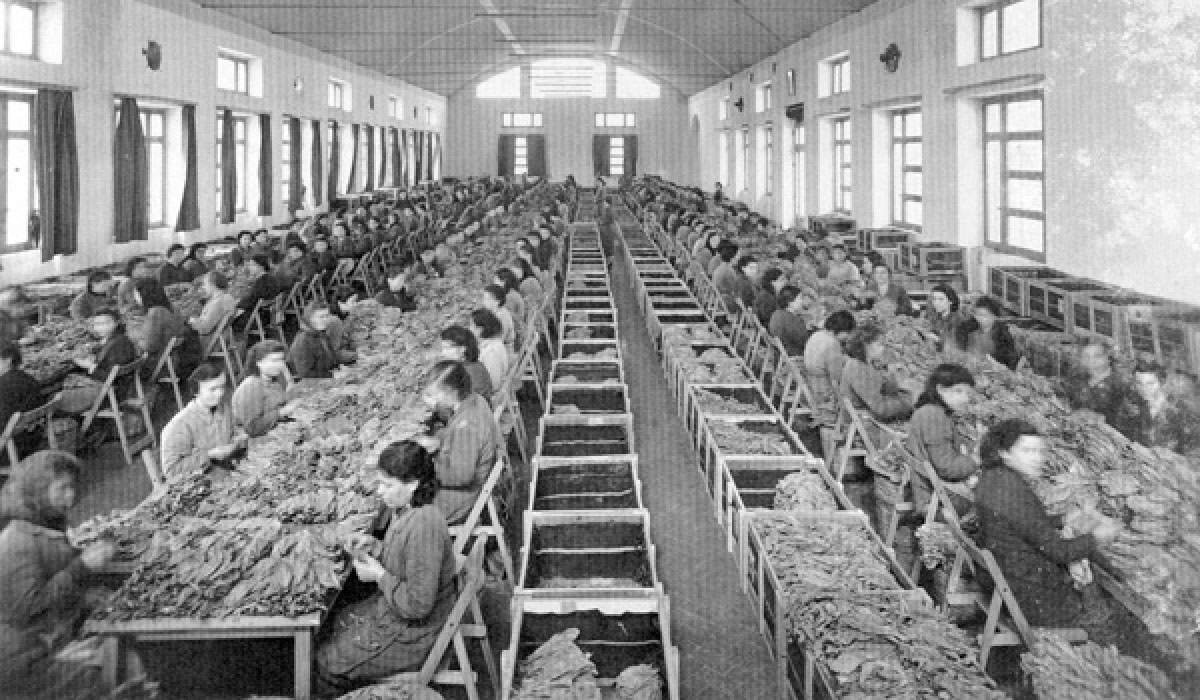

Salento was particularly suitable for tobacco farm thanks to its boundless lands and favourable climate. In 1812, with the establishment of Kingdom of Naples, the first “Tobacco Manufacture in Salento” arose. In this manufacture up to 12.000 tons of tobacco leaves were processed, coming from the production of 24 different Salento municipalities.

Tobacco is the undisputed heritage of Salento, which has been its cradle. During the summer, it was possible to see rectangular structure outside houses, the so-called tobacco looms. On these looms tobacco leaves were put for sun drying. Consequently, the peculiar scent of tobacco spread in the air among neighbourhood.

Tobacco farm tradition had been one of the main economic sources for Salento families at the time. In fact, tobacco and “tabacchine” history culminate in the first years of 1900, when a whole family worked for it from April to November. Even now “tabacchine” are seen as a symbol of worker women and proletarian women revolution in 1990.

From seeding to harvest, until leaves stringing

In Salento, tobacco plantation by “tabacchine” started with tobacco seeding. This process asked for skilled hands and took place in a piece of land designated for plantation and called “ruddhre” in dialect. This rectangular area was levelled with a rake in order to put “rumato”, the manure used as organic fertiliser. Then tobacco seeds were thrown, mixed with cinder, and land was watered. Once seeds were ready to be planted, they were uprooted and put in little wooden boxes called “cascette”. Then they were covered with jute canvas and planted in a different soil.

The harvest took place at first lights: it was a process involving whole families, children included. Specifically, tobacco leaves harvest was made 4-5 times in order to take as much as possible from the plant. It took about one week.

Once the harvest was completed, families went home and, seated in circle, started the fundamental phase of stringing, in dialect “nfilatura”. A large steel needle with twine was used to insert tobacco leaves and when all strings were completed, they were hanged to looms and sun drying started. Looms were called “tiralettu” and after the sunset they were moved in the house.

Once tobacco was dried, it was given to tobacco manufacture in wooden boxes covered with jute canvas.

The hard work of “tabacchine”

Tabacchine role was fundamental in all stages of tobacco plantation. They were Stakhanovite worker, fully devote to work. This led to a chant, often sung by them, which made their work evocative and described their role for almost a century.

Fimmene fimmene ca sciati allu tabaccu

Women, women going to plant tobacco

ne sciati doi e ne turnati quattru.

You are two on the way there and you are four on the way back

Ci bu la dici cu faciti lu tabaccu

Who tells you to go working for tobacco?

la ditta nu bu dae li tilaretti.

Firm does not give you any loom.

Ca poi li sordi bu li benedicu

I will bless your money

bu nne ccattati nuci de Natale.

And with them you will buy walnuts for Christmas.

Te dicu sempre cu nu chianti lu tabaccu

I always tell you not to plant tobacco

lu sule è forte e te lu sicca tuttu.

Because sun is too hot and dries out all of it

Fimmene fimmene ca sciati alle ulìe

Women, women going to harvest olives

cugghitene le fitte e le cigghiare.

Harvest the ones inside and outside the net.

Fimmene fimmene ca sciati a vindimmare

Women, women going to harvest grapes

e sutta lu cippune bu la faciti fare.

And in the vineyard you were harassed.

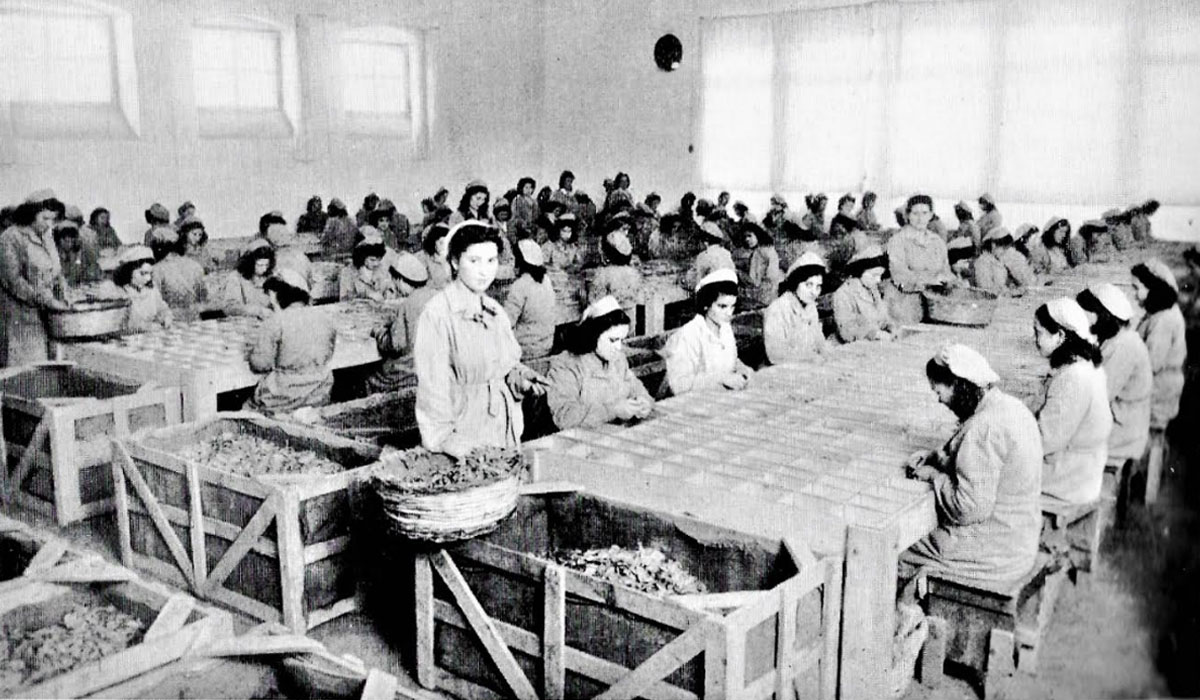

“Tabacchine” often started their work later in November, when tobacco leaves were already dried out. They dealt with winnow, diving leaves per colour and quality into wooden boxes, throwing away the so-called “rumasuje”, the residues.

Then leaves were divided into small bunches in order to be pressed. Tobacco was pressed and leaves were put in a wood stove in order to make them ripen. Meanwhile other “tabacchine” made “ballette”, a tobacco bale made based on weight and quality.

There was a woman worker supervising all stages in order to avoid setbacks and imperfections; she was called “mescia”, which in dialect means teacher. Tobacco bales were put in a room in contact with sulphur to avoid decay and few days later there was another inspection by “mescia”. Since tobacco was used to make cigarettes, a part was given to the ones who needed it and the remaining part was given to monopoly manufactures in order to evaluate taste and smell.